Dropshipping vs Bulk Procurement: Which is Better Suits Your Startup Eyewear Business?

Before we delve into the crucial discussion on "Dropshipping vs Bulk Purchasing", we have to think about this question: As fellow entrepreneurs navigating the competitive eyewear industry, have you ever pondered this core issue: Among all the complex startup considerations, what would you identify as the most non-negotiable, paramount principle that an eyewear startup simply cannot afford to compromise?

For a startup eyewear frame brand, product quality consistency and customer trust are not merely operational guidelines, but the very foundation of survival and growth. Once lost, the brand will lose its foothold in the market.

If an eyeglasses frame purchased today differs in detail from one bought next time, or if products from the same batch exhibit inconsistent quality, customer confidence in the brand will quickly collapse. These issues, no matter how minor, are immediately noticeable to users, who are unlikely to give the brand a second chance. The startup team must enforce extreme rigor in supply chain and quality control, even at the cost of short-term profits, rather than compromising on standards.

Eyewear frames may seem simple, but their consistency directly determines long-term wear comfort and durability—will the plating on metal frames peel easily? Is the acetate frame’s flexibility sufficient to prevent breakage? Are the hinges smooth and durable enough to withstand repeated use? Even the slightest oversight in these details becomes apparent the moment the user handles the product.

For example, a deviation of just a few millimeters in the nose pad positioning can cause discomfort, or uneven tension in the frame's temple arms can make prolonged wear unbearable. Worse yet, if product quality fluctuates noticeably between batches, repeat customers may perceive the brand as "unreliable," suspecting their initial positive experience was merely luck.

Such inconsistency is fatal for a startup eyewear brand, as early adopters—often the brand’s most passionate advocates—will voice their disappointment, turning word-of-mouth negative and plunging the brand into a trust crisis at its most vulnerable stage.

Building customer trust hinges on every single frame maintaining a consistent standard. Consumers may accept iterative improvements, but they will not tolerate a "lottery-like" shopping experience—especially for a product like eyewear, which requires long-term use and precise personal fit.

The startup team must obsess over supply chain control from day one, ensuring every step—from raw materials to production—is tightly managed. For instance, the alloy composition of metal frames must remain uniform to prevent variations in plating quality between batches, while acetate frames demand precision in injection molding to avoid uneven thickness or rough edges. Even if the initial product lineup is limited, every unit shipped must meet the same exacting standards.

This consistency isn’t just about avoiding negative reviews—it’s about fostering long-term customer loyalty. When buyers repeatedly find that an eyewear brand’s frames deliver the same comfort and durability with every purchase, trust becomes instinctive, and they’re far less likely to gamble on alternatives. Once that trust is broken, customer attrition accelerates beyond expectations. For example, if a brand known for "lightweight" frames cuts corners in production, resulting in a heavier product, users will instantly sense the discrepancy and question the brand’s entire quality system. The cost of rebuilding that trust could far exceed what the startup anticipates.

Thus, for an eyewear frame startup, quality consistency isn’t a high standard—it’s the baseline. Customer trust isn’t earned through marketing—it’s accumulated through relentless, unwavering product performance. In a competitive market, only brands that meticulously control every detail of every frame, year after year, will ultimately earn their customers’ unwavering preference.

In-Depth Analysis of Dropshipping Model

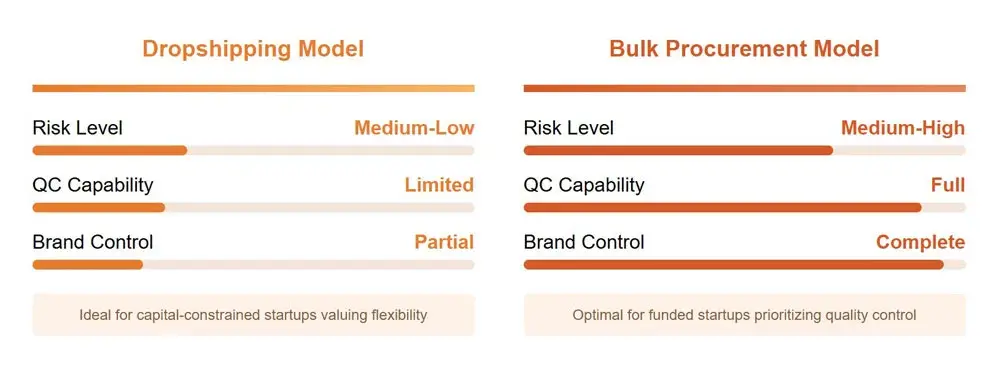

The dropshipping model presents a double-edged sword for emerging eyewear brands. Its most compelling advantages lie in its remarkably low barrier to entry and exceptional operational flexibility. Specifically, startups can completely avoid two major pain points of traditional retail models: first, the elimination of upfront inventory investments that typically range from hundreds of thousands to millions, providing crucial relief for cash-strapped entrepreneurs; second, complete exemption from complex operational aspects like warehouse leasing, inventory management, and logistics distribution. In practice, when customers place orders on brand websites or e-commerce platforms, order information is automatically synchronized to suppliers through ERP systems, with suppliers handling the entire process from picking to packaging and shipping. This "asset-light" model allows startups to concentrate limited resources on critical areas like brand building, user experience optimization, and marketing.

However, this seemingly perfect model conceals multiple risks. The most critical issue is the complete loss of supply chain control. Eyewear, as a product combining functionality and fashion, demands exceptional quality consistency. Under dropshipping, every critical quality parameter - from frame material selection to manufacturing processes, from plating quality to hinge adjustment - depends entirely on the supplier's quality control standards. In reality, batch-to-batch variations may include visible color discrepancies, uneven or peeling plating, inconsistent hinge tension, and other defects. More concerning are subtle parameters like nose pad symmetry and temple elasticity coefficients - minor deviations that directly impact wearing comfort and may even cause visual fatigue or health issues.

Logistics present another minefield. Without direct control over shipping processes, suppliers may encounter delays, wrong/missing items, or substandard packaging. During peak seasons, suppliers might prioritize larger clients, indefinitely postponing startup brand orders. Worse still, inconsistent packaging materials across different suppliers create varied unboxing experiences that severely damage brand image consistency.

Profit margin constraints represent another significant challenge. In dropshipping, suppliers already claim substantial profit shares, leaving brands with typically just 30%-40% gross margins. In the fiercely competitive eyewear market where price wars are commonplace, startups unable to differentiate through unique branding or innovative marketing easily fall into a vicious cycle of "low-price competition → slim profits → compromised quality."

Comprehensive Evaluation of Bulk Procurement Model

Bulk procurement offers eyewear startups more reliable quality assurance. This model's core advantage lies in maintaining firm control over product quality. In practice, teams can implement rigorous supplier vetting processes to partner with factories possessing robust quality management systems. Before ordering, brands can request detailed quality reports including frame material composition analysis, plating wear-resistance test data, hinge durability results, and other key metrics.

A comprehensive bulk procurement quality control system typically involves three critical phases: First, pre-production sample approval, requiring 3-5 prototypes for thorough inspection and wear testing; second, mid-production inspections conducted by professional QC teams or third-party agencies; finally, post-delivery final inspections ensuring every batch meets established standards. This end-to-end quality management system maximizes product consistency and reliability.

Regarding commercial terms, bulk procurement often secures more favorable conditions. Price advantages typically offer 15%-30% discounts for large orders; customization options include exclusive packaging, brand engraving, and special treatments; production scheduling priority ensures timely delivery. P requiring tens of thousands of dollars initial investments. For diverse product lines, initial inventory costs may reach hundreds of thousands. roof Eyewear exemplifies this approach - their bulk procurement of FSC-certified wood frames and recycled aluminum not only guaranteed product quality but successfully built a distinctive eco-friendly brand image commanding 2-3x premium over conventional eyewear.

bulk procurement imposes higher capital requirements. For mid-range metal frames, minimum order quantities typically range 300-500 units, requiring tens of thousands of dollars initial investments. For diverse product lines, initial inventory costs may reach hundreds of thousands. More critically, inventory risks emerge when market response underperforms - stagnant stock not only ties up capital but may depreciate due to obsolescence. Therefore, accurate market forecasting and flexible inventory strategies become paramount. Startups should adopt "small-batch multi-order" procurement strategies, validating market response through pre-sales or crowdfunding before adjusting procurement plans. Simultaneously, establishing scientific inventory turnover monitoring mechanisms enables timely promotional clearance of slow-moving products.

For startup teams with sufficient capital, bulk procurement is the recommended approach as it allows complete control over product quality—from raw material selection and manufacturing processes to packaging design and logistics management—ensuring precision at every stage of production.

For those operating with limited funds, a viable alternative is to implement a Dropshipping model while introducing a dedicated quality inspector role. This professional serves as the critical bridge between the team and suppliers, acting as the ultimate "gatekeeper" of product standards. The inspector must rigorously evaluate each shipment, examining plating consistency, hinge tension, nose pad symmetry, and packaging integrity to ensure every unit meets brand specifications. While this additional quality control layer increases operational costs, it significantly mitigates the inherent risks of Dropshipping by maintaining user experience standards and preventing brand reputation damage caused by quality fluctuations.

However, regardless of the supply chain model chosen, the fundamental principle remains unchanged: long-term success in the eyewear industry is built exclusively on product consistency and earned consumer trust. Quality determines whether customers repurchase, while trust dictates their willingness to advocate for your brand. Warby Parker's rise as a standout DTC brand exemplifies this principle—even while utilizing Dropshipping, they embedded quality and trust as non-negotiable pillars of their business model through rigorous supplier vetting and transparent prescription services, ensuring every pair met promised standards.

When evaluating supply chain options, startups must therefore look beyond short-term cost savings or operational convenience. The decisive questions are: Can this model guarantee unwavering product consistency? Will it foster enduring consumer confidence in our brand? Only by treating these two factors as absolute imperatives can a brand establish true market resilience and achieve sustainable growth in this competitive landscape.