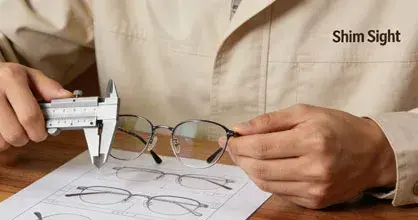

Bridge Size in Eyewear — Professional Guide for Designers & OEMs

Bridge Size of Eyewear Frames — A Technical Guide for Design, Sampling & Fit

A compact B2B technical reference for eyewear designers, OEM/ODM teams, and optical product managers.

Introduction

Bridge size — often shown as the middle number in a frame spec (e.g., 53-17-140) — is one of the most influential yet frequently misunderstood parameters in eyewear engineering. For designers, prototyping engineers, and B2B buyers, bridge width affects structural stability, wearer comfort, visual balance, weight distribution, and compatibility across markets.

This technical guide explains bridge size across the product lifecycle: product design, prototyping & manufacturing, and end-user fit. The article concludes with a professional overview of nose pad types and materials, because pads directly modify the effective bridge width.

1. Understanding Bridge Size: More Than a Number

The bridge size (DBL / Distance Between Lenses) refers to the minimum horizontal distance between the two inner rims. However, the functional bridge — what the user feels — depends on bridge curvature, nose pad height and angle, pad material thickness, and frame material behavior.

Effective Bridge Width (EBW) is the perceived bridge width after pads and contact geometry are applied. For B2B contracts, always specify EBW targets in addition to the printed DBL.

2. Bridge Size in Product Design

2.1 Functional Role of the Bridge

- Supports the majority of the frame weight and stabilizes the front alignment.

- Distributes pressure across the nasal area; impacts lens centration and PD alignment.

- Influences pantoscopic tilt and the wearer’s field of view.

2.2 Geometry & Anthropometrics

Design must account for population nasal differences. Key parameters:

- East Asian: wider nasal base, lower bridge → need smaller EBW, higher / thicker pads.

- Western/European: higher bridge, narrower base → larger DBL acceptable.

- Children: small DBL & deep saddle shape required.

2.3 Bridge Shape: Aesthetic & Structural Impact

Common shapes and notes:

Keyhole Bridge

Slimming effect, room on nasal crest — popular in acetate/vintage lines.

Saddle Bridge

Broad contact, excellent weight distribution — preferred for low-bridge users.

Designers use bridge shape as a brand identity element while ensuring functional fit for the target demographic.

2.4 Material Influence

Material behavior alters tolerance and EBW:

- TR90 / injection plastic: flexible, forgiving tolerances, suitable for global fit variants.

- Acetate: rigid, requires accurate bridge dimensions.

- Metal: most adjustable via pad arms; preferred for precise PD alignment.

3. Bridge Size in Prototyping & Manufacturing

3.1 Effective Bridge Width (EBW) in Sampling

EBW differs from DBL due to pad arm angle, pad height, and pad thickness. Example: a 17 mm DBL can feel like 14–19 mm depending on pad setup. For high-accuracy products (progressives, safety eyewear), record EBW and pad geometry in the technical pack.

3.2 Production Tolerances

Recommended tolerances for bridge size:

- Metal: ±0.3 mm

- Acetate: ±0.5 mm

- TR90 injection: ±0.8 mm

QC must include EBW checks, pad arm symmetry, and centration alignment.

3.3 Distortion Risks During Assembly

- Soldering or heat processes can narrow or widen the bridge.

- Over-polishing may alter the DBL; welding can deform pad arms.

Best practice: add post-assembly EBW validation and wear trials for initial batches.

4. Bridge Size and the End-User Wearing Experience

4.1 Problems from Incorrect Bridge Size

Too wide: slipping, PD misalignment, poor pantoscopic angle. Too narrow: nose pinching, redness, high front position and optical discomfort. These issues raise returns and negative reviews in B2B channels.

4.2 Impact on PD & Visual Comfort

Bridge geometry affects optical center alignment — critical for progressives and high-index lenses. Minor centering errors can produce prism imbalance and wearer fatigue.

4.3 Aesthetic Fit

Proper bridge design centers the frame on the face, balancing brow line and cheek contours and improving perceived product quality — especially important for fashion and premium collections.

5. Nose Pads — Types, Materials & Their Influence

5.1 Nose Pad Types

- Screw-in pads — replaceable, common in metal frames, allow angle tuning.

- Push-in (snap) pads — faster assembly for value models.

- Adhesive soft pads — temporary fit corrections (not recommended as permanent solution).

- Molded / integrated pads — found in acetate/TR90, aesthetic but not adjustable.

- Air-cushion / gel pads — premium comfort and load distribution.

5.2 Nose Pad Materials

Silicone

Soft, high friction, various durometers — ideal for low-bridge users.

PVC

Economical, moderate comfort — common in entry-level lines.

TPU / Medical-grade elastomer

Hypoallergenic, premium feel — recommended for long-wear products.

Acetate / Metal pads

Aesthetic, less cushioning — used for high-style designs.

5.3 How Pads Modify EBW

Nose pads can change EBW by 2–6 mm depending on thickness, arm angle, and compressibility. For example, a 17 mm DBL may function as 14 mm EBW with thick 5 mm pads at a narrow angle. Always include pad spec (thickness, arm length, and angle) in tech packs.

6. Best Practices for OEM/ODM and Brands

- Designers: specify DBL + EBW targets, include pad geometry, and use anthropometric datasets.

- Factories: maintain tolerances, QC EBW, record pad arm angles, and run wear trials by market.

- Buyers: request regional prototypes (Asian/Western), confirm pad materials, and test with end-user panels.

7. Conclusion

Bridge size is a multifactorial parameter — not merely a printed number. EBW, pad geometry, and material behavior together determine wearer comfort, optical alignment, and return rates. For eyewear professionals, mastering bridge design reduces post-market issues and increases product success across global channels.

If you want, ShimSight can provide EBW calculators and sample test protocols to integrate into your product development cycle.

Read More