Bridge Size Standards — Market Reference

Recommended bridge ranges and design notes for eyewear product development and OEM sourcing. Values are typical recommended ranges (in millimetres).

| Market / Segment | Typical Nose Profile | Recommended Bridge Range (mm) | Recommended Nose Pad Height* (mm) | Practical Notes |

|---|---|---|---|---|

| East Asia (China, Korea, Japan) | Lower nasal root, flatter dorsum | 13 – 16 | 3.5 – 6.0 | Consider Asian-fit variants (higher pad height, shorter effective bridge). Wider pad footprint or built-in saddle bridge. |

| Southeast Asia (Indonesia, Philippines, Vietnam) | Low-to-medium nasal root, broader nose base | 14 – 17 | 3.0 – 5.5 | Balance between pad height and bridge width; many prefer slightly higher pad for stability. |

| South Asia (India, Pakistan, Bangladesh) | Medium-to-high nasal root, wider bridge in some subgroups | 15 – 18 | 3.0 – 5.0 | Offer a mix of saddle and standard bridges; consider larger lens PD allowance. |

| Middle East / North Africa | Medium-to-high nasal root, variable nose base | 16 – 19 | 2.5 – 4.5 | Often wider overall frame widths; keep options for stronger temple hold. |

| Europe (Western & Central) | Higher nasal root, narrower nose base | 16 – 19 | 2.0 – 4.0 | Standard bridges and adjustable pads work well; acetate frames require precise bridge specs. |

| North America | Higher nasal root, varied base widths | 16 – 19 | 2.0 – 4.5 | Large market variety — offer multiple bridge widths per SKU where possible. |

| Latin America | Medium nasal root, broader base in many subgroups | 15 – 18 | 2.5 – 5.0 | Good market for hybrid TR90 + metal temple designs—provide mixed-fit options. |

| Africa (Sub-Saharan) | High variability; medium-to-high nasal root common in many areas | 15 – 19 | 2.5 – 5.0 | Highly heterogeneous — recommend regional sampling and adjustable pads. |

| Children / Youth | Small nasal base, low nasal root (young children) | 12 – 15 | 3.0 – 6.0 (higher relative to adult) | Use flexible TR90 + spring hinges; smaller PD and narrower total width required. |

*Nose Pad Height = vertical distance from frame plane to pad contact point (guideline). Actual pad geometry and pad arm length also affect fit.

The bridge size is a very important dimensional parameter for eyeglass frames. It influences the aesthetic concept of frame design and largely determines the wearing experience.

Practical Nose-bridge / Bridge formulas (for designers & spec sheets)

1) Effective Bridge Width (approx.) — EB

Use this to estimate the horizontal spacing between the two pad contact surfaces as the wearer experiences it (mm):

EB ≈ MB + 2 × (PT × cos(θ))

- EB = Effective Bridge width (mm) — horizontal clearance between pad contact centres.

- MB = Marked Bridge on spec (mm) — nominal bridge value on temple/box.

- PT = Pad Thickness or Pad Offset (mm) — vertical thickness or projection of pad from pad arm pivot.

- θ = Pad Tilt Angle from vertical (degrees). For small angles, cos(θ) ≈ 0.97–1.00.

Notes: this is an approximation that treats pad offsets mainly as horizontal contributors. Real pad geometry (pad arm length, nose curvature, pad footprint) modifies the result; use 3D CAD or fit samples for fine tuning.

2) Required Marked Bridge for Target Fit — MB_req

MB_req ≈ Target_EB − 2 × (PT × cos(θ))

If you determine a target effective bridge for a user segment (Target_EB), compute the nominal MB to stamp on the frame.

3) Bridge Fit Guidance (selection rule)

Choose MB so that |User_Nose_Base_Width − EB| ≤ 1.0 mm

User_Nose_Base_Width = measured horizontal width across user's nasal base at intended pad contact points. Aim for EB within ±1 mm for optimal comfort; +/-2 mm may be acceptable for flexible TR90.

Worked numeric example

Example: Marked bridge MB = 17 mm, pad thickness PT = 3.0 mm, pad tilt θ = 15°.

- cos(15°) = 0.965925826 (approx).

- 2 × (PT × cos(θ)) = 2 × (3.0 × 0.965925826) = 2 × 2.897777478 = 5.795554956.

- EB ≈ MB + 5.7956 = 17 + 5.7956 = 22.7956 mm ≈ 22.8 mm.

Interpretation: a frame marked 17 mm with those pads will behave like ~22.8 mm effective bridge — choose smaller MB if target EB is ~18–20 mm for your market.

Design & testing tips

You may want to check Design Guide for Bridge Sizing

- For TR90 injection frames, allow ±1 mm tolerance around EB (material elasticity). For acetate, aim for ±0.5 mm.

- Provide at least two bridge variants per popular SKU (e.g., 15 mm and 17 mm) when serving international accounts.

- Use adjustable metal pad arms for broader market coverage (reduces need for multiple MB SKUs).

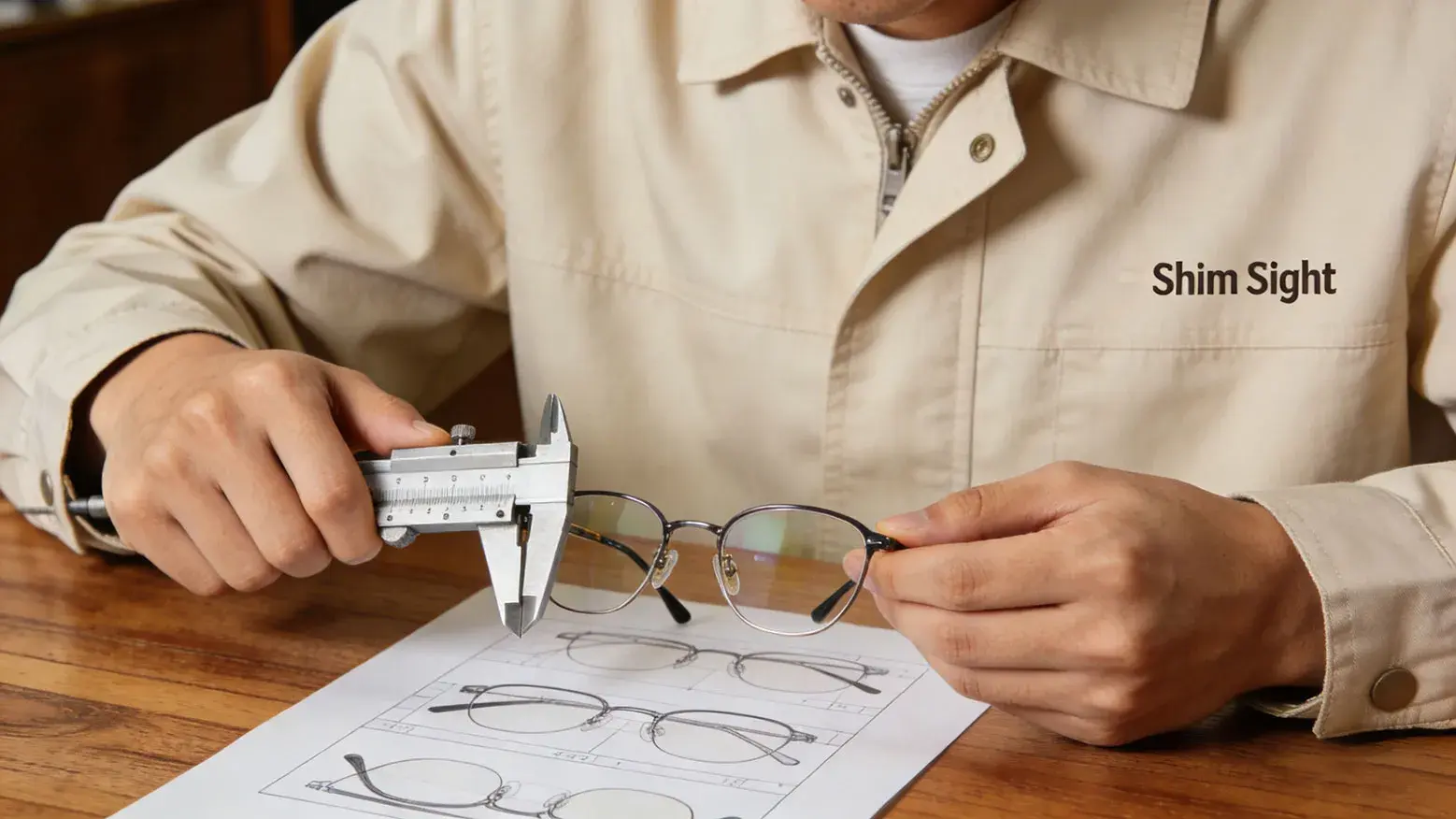

- Include pad geometry drawings (pad height, pad arm length, pad offset) in tech packs to ensure consistent fit during OEM production.

Read More