Understanding Demo Lenses in the Optical Industry

This is a complete guide for eyewear manufacturers, eyewear wholesalers, and private-label partners on how demo lenses support structure, presentation, and brand consistency across global optical markets.

1. What Is a Demo Lens?

In the eyewear manufacturing chain, a demo lens—also known as a display or sample lens—is a transparent or translucent lens fitted into optical frames before prescription lenses are installed.

Demo len's purpose is not optical correction, but rather to maintain the frame’s shape, showcase its aesthetic, and support brand presentation during sales or logistics.

In B2B production and wholesale operations, demo lenses play an essential technical and marketing role, ensuring each eyewear frame leaves the factory floor with the same precision it was designed for.

2. Why Demo Lenses Matter for Manufacturers and Distributors

For eyewear factories and distributors, the demo lens is far more than a placeholder. It is a critical structural and presentation component of every eyeglass frame.

During assembly, it preserves the frame geometry, especially for lightweight metal or mixed-material designs. This prevents warping or distortion during bulk shipment and storage.

On the display side, a fitted demo lens provides a complete look that mirrors the final retail product—essential for photography, trade fairs, and showroom presentation. When distributors receive samples or ready-stock frames, a clean, polished demo lens helps communicate craftsmanship and design integrity even before prescription fitting.

3. Materials and Finishing of Demo Lenses

The quality and type of demo lens used directly influence how a frame is perceived in the market. Most lenses are made from lightweight plastics such as acrylic (PMMA), polycarbonate (PC), or nylon blends. Each material offers a balance of durability, transparency, and cost efficiency:

- Acrylic (PMMA): High clarity, lightweight, and cost-effective—ideal for mass-market frames.

- Polycarbonate (PC): Impact-resistant and flexible, used for premium or export-grade frames.

- Nylon / CR-39 Variants: Used in boutique production for optical clarity and anti-yellowing properties.

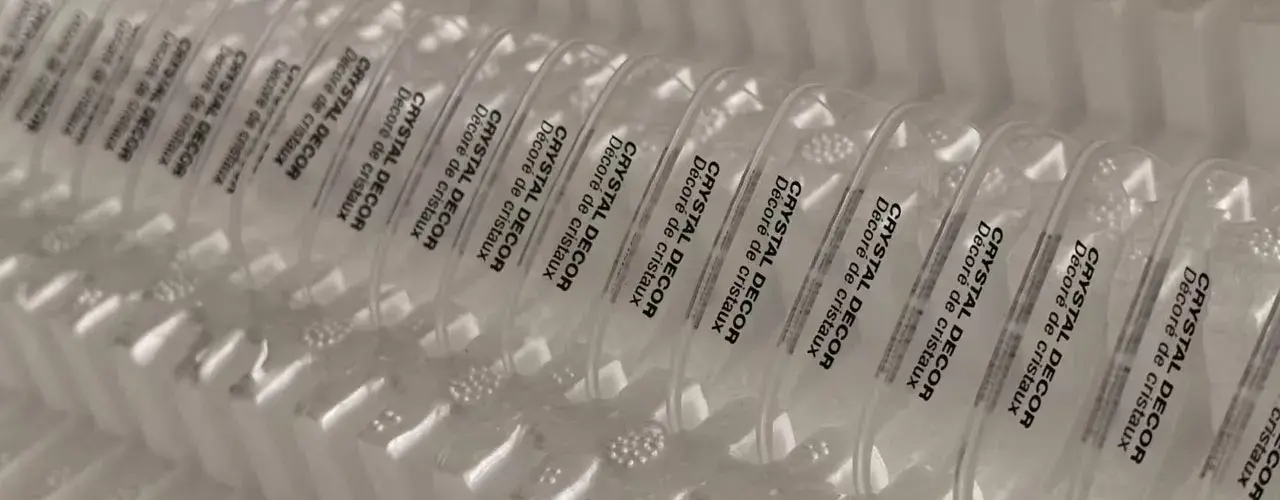

Beyond materials, finishing plays an equally vital role. Demo lenses may feature a glossy clear surface for visual depth, a frosted finish for minimalist styling, or light smoke tints that simulate completed eyewear. Many factories include printed markings—such as size, model number, or brand logo—using UV or silk printing techniques for professional presentation.

4. Demo Lenses vs. Functional Lenses

From a technical perspective, demo lenses differ fundamentally from functional lenses. They contain no optical power, no anti-blue-light or UV protection, and are generally thinner. Their function is mechanical and aesthetic, not corrective. The curvature is shallow, purely to maintain alignment between the eyewire and nose bridge during handling and packaging.

In retail or optical workshops, demo lenses are always replaced with prescription or performance lenses before customer delivery. For B2B buyers, understanding this distinction helps align product specification sheets and export documentation more accurately.

5. Customization and Branding Options

One of the most overlooked branding tools in eyewear manufacturing is the demo lens. Because every frame leaves the factory fitted with one, it becomes a powerful touchpoint for brand identity. Manufacturers and OEM partners can customize demo lenses with:

- Logo printing — brand names, collection titles, or design codes.

- Optical size markings — e.g., “52□18 140” for professional presentation.

- Custom tinting — light grey, smoke, or gradient tones to match branding palettes.

- Matte or transparent finishes — depending on regional market preference.

For global distributors, such custom demo lenses strengthen visual consistency across packaging, product pages, and retail displays. For private-label buyers, they provide immediate differentiation in an increasingly competitive market.

6. Environmental and Quality Standards

As sustainability gains importance, factories now offer eco-friendly demo lens materials—such as recycled PMMA or bio-based resins that reduce environmental impact without sacrificing clarity. High-end suppliers also perform quality checks on parameters like transmittance rate, surface hardness, and UV stability. When exporting to Europe or North America, demo lenses can comply with REACH and RoHS standards, ensuring safe, environmentally responsible production.

7. Replacement and Handling in Optical Chains

In retail operations, demo lenses are temporary by design. Once the customer selects a frame, the optician removes the demo lens and replaces it with prescription or blue-light lenses. However, for wholesale distributors and B2B buyers, maintaining pristine demo lenses during handling is crucial. Scratched or warped demo lenses may compromise a frame’s appearance, reducing sell-through potential.

Many eyewear factories, including Shim Sight’s supply chain, use protective films over demo lenses for large export batches. This ensures that upon unpacking, the frames remain clean, clear, and showroom-ready.

8. Why Demo Lenses Add Value to B2B Eyewear Production

In a B2B context, demo lenses serve as a quiet but indispensable part of value creation. They ensure structural protection during mass production, deliver visual completion during brand presentation, and support marketing consistency across hundreds of SKUs. When designed correctly, a high-quality demo lens helps reduce warranty claims, enhance brand perception, and accelerate sales conversion—making it one of the most cost-effective investments in the eyewear manufacturing process.

Whether for bulk ready-stock supply or OEM development, every optical frame fitted with precision-cut demo lenses communicates reliability and professionalism—traits that define successful global eyewear brands.

At Shim Sight Eyewear, all optical frames are equipped with demo lenses made from optical-grade PMMA or PC, offering customizable transparency, logo printing, and OEM-friendly packaging options for global wholesale and private-label partners.